Why We Partner for Cable

We don’t own a cable plant (well, not yet, anyway). Our focus is on design, assembly, quality control and delivery. At the moment there is not a huge need for us reinvent the wheel when the top OEMs have been doing this for decades. By leveraging their scale and expertise, we can stay lean and avoid a massive capex for extrusion and jacketing lines.

It also helps us to stay focused on what we’re doing here - building the systems that turn bulk cable into awesome finished connectivity products, leaving our cable partners to do what they do best

One real key is open access to world-class optical fibre (including specialty fibres), avoiding poor quality control often found with smaller fibre drawing operations.

There’s also something nice about sharing R&D and innovation between organisations. We bring a lot of experience and thought about cable design, and we’re happy to help our partners to drive new concepts, technologies and designs into the market.

Ultimately it really helps us to rapidly execute. Our partners have the capability to test and qualify across IEC and Telcordia specs (among others), so there is very little scale up timeframe needed.

Vetting the Top 5 OEMs

Not all OEMs are created equal. There are hundreds or thousands of cable manufacturers, many of them exceptionally poor. We put candidates through a gauntlet of real-world tests before talking price. Of critical importance to us is the ability to scale. Does the parter support manufacture of cable where we need it?

We’re strict on compliance, too. Our partners are ISO-certified, technically complaint, socially responsible, and fully auditable—across all sites. This is a non-negotiable for our customer base.

We also have some relatively strict controls across quality, operations and tracability. We make sure that raw materials are controlled, and that new raw materials are not used without qualification.

Spec Harmonisation Across Borders

Our optical fibre and fibre cable specs are non-negotiable, which means that we need deep supply chain alignment.

Central for us is consistent glass. Although people like to consider all glass the same, it really isn’t. For us, our choice of partners gives us immediate access to consistent, high-quality optical fibre, whether the cable is manufactured in Japan, Germany, the USA or China. The same applies for other materials like polymers, FRP and aramid. All of those need the same specification, wherever we take delivery.

It’s also really important for us that the Sdesigns we work with have been manufactured and are fully qualified, they don’t just exist on paper.

Quality Control & Testing Regime

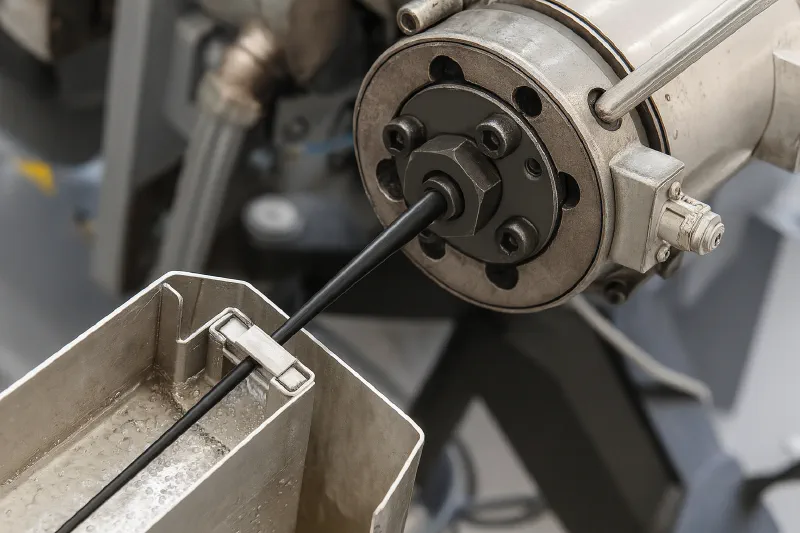

You don’t get to call yourself “high-performance” without proof. We have fairly rigorous requirements for quality control generally. Typically for cable we want to see complete cable qualification, including crush, impact, flex and torsion tests (among others). We also look for preventative controls in place with modern process control and things like in-line micrometer checks. We also like to make sure we understand the testing process. What is tested in each production batch, and what is tested only in qualification of a design. Choosing one of the key OEMs allows us to leverage these capabilities in a way that we just could not if we established our own (smaller, less mature) capability.

Supply Chain Agility

Our relationships with top cable OEM’s is a force multiplier. It allows us to leverage the global footprint and capability to deliver a global manufacturing footprint. Production lines in EMEA, APAC and the Americas ensure your cable is made close to your project, cutting transit time and risk.

The relationships also give us great elastic scaling ability. From small trial batches to 1,000 km+ orders, we can scale output without the need for multi-year planning that would plague us with a smaller self-owned facility.

It’s also super cool that choosing the right partner can give you access to multiple plants per region. This really is the ultimate fail-over scenario. Manufacturing supply stays live even if one site hits downtime.

What This Means for You

There are some super tangible benefits for ScaleFibre clients that result from these relationships.

- Access to premium cable at scale. Proven designs, qualified materials, and immediate availability across standard and specialty fibres.

- Consistent delivery, anywhere. Global production footprint means short transit times and fewer delays.

- Assured quality. Full transparency across testing regimes, material controls, and manufacturing processes, with data to back it up.

Scale with us. Feed us your spec, and we’ll handle the rest, no delays, no excuses.